Os fabricantes de óleo de cozinha enfrentam desafios cada vez maiores devido a baixas margens de lucro, variação na qualidade da matéria-prima e mudança nos hábitos dos consumidores. Para melhorar o desempenho da produção e reduzir os custos operacionais, é necessária uma tecnologia de medição inovadora. Por meio da otimização orientada e consistente do processo de refino, os operadores podem reduzir o tempo parado e as rejeições e ainda aumentar o valor agregado de seus sistemas, sem sacrificar a qualidade do produto.

Principais fatos

218

million metric tons

of edible oils were produced worldwide in the crop year 2022/2023. Source: www.statista.com

Otimize seu processo de refino de óleo comestível

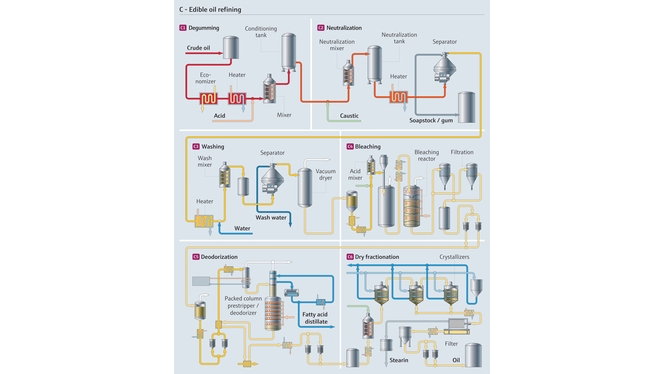

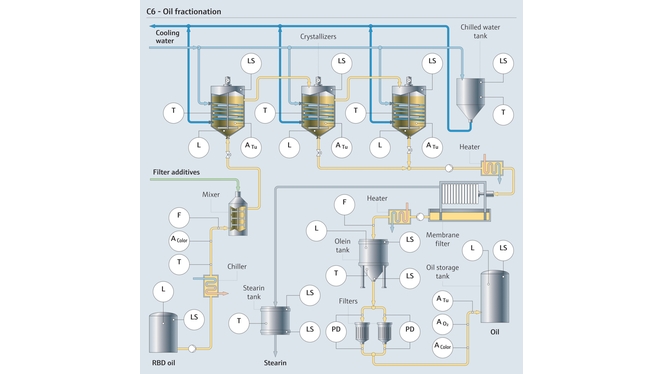

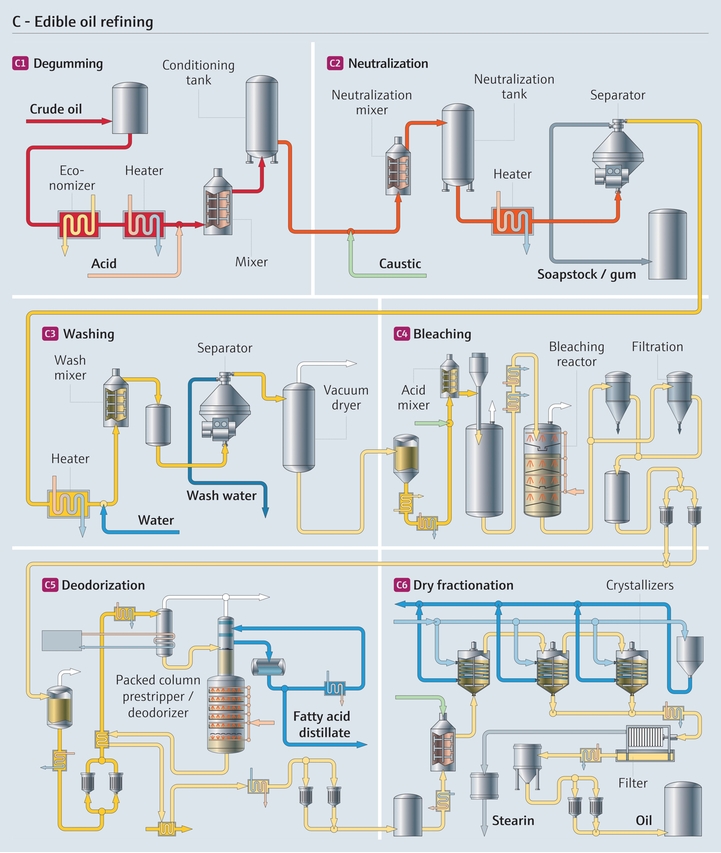

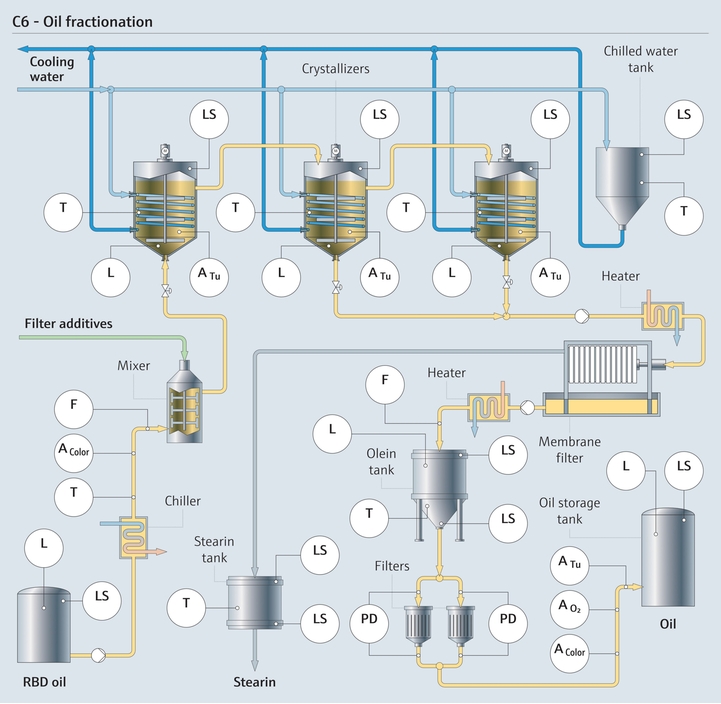

Saiba mais sobre como otimizar seu refino de óleo comestível em todas as etapas do processo - desde degomagem, neutralização, lavagem, branqueamento, desodorização até fracionamento a seco.

Entrega de matérias-primas

O monitoramento da quantidade e qualidade da matéria-prima começa no ponto de entrega.

Nosso conhecimento em campo

Nossos instrumentos de medição baseados na tecnologia radar monitoram o nível de abastecimento dos silos e tanques de armazenamento de forma precisa e contínua, esteja a matéria-prima no estado líquido ou no estado sólido.

- Conte com o Micropilot FMR67 com a tecnologia de 80GHz para as mais altas demandas em medição de nível de sólidos.

- Use MicropilotFMR62 para medição de nível em líquidos agressivos ou aplicações com requisitos de higiene.

- Reduza os custos de inventário e aumente a produtividade com visibilidade completa do estoque, graças à nossa solução de gerenciamento de inventário

Do óleo bruto ao óleo de cozinha de alta qualidade

Durante o refino do óleo de cozinha, são removidos do óleo bruto os componentes indesejados, como as substâncias túrbidas ou outros materiais que afetam o cheiro e o sabor.

Nosso conhecimento em campo

Garantir a qualidade do produto em cada um dos processos requer o monitoramento constante de parâmetros críticos como temperatura, pressão e vazão.

- Descubra nosso portfólio completo de produtos para medição da temperatura, como sensores de temperatura compactos, sensores de temperatura modulares, poços para termoelementos, unidades eletrônicas de medição e transmissores.

- Escolha o medidor de vazão mais adequado para as necessidades de seus processos usando um portfólio abrangente.

- Atualmente, a tecnologia de medição de pressão é frequentemente usada para medir líquidos, materiais pastosos e gases. Com uma ampla variedade de tecnologia de sensores, oferecemos instrumentos perfeitos para qualquer aplicação.

Segurança do processo em todas as faixas de temperatura

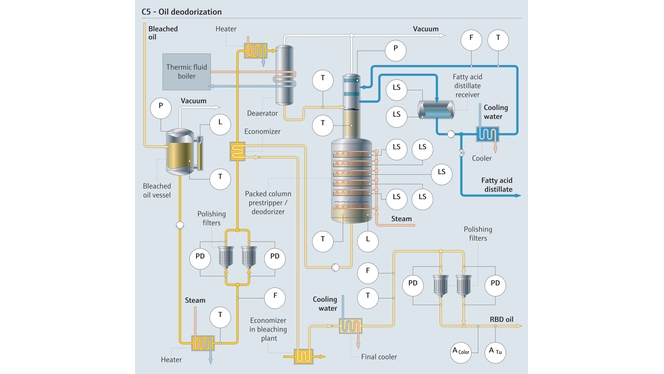

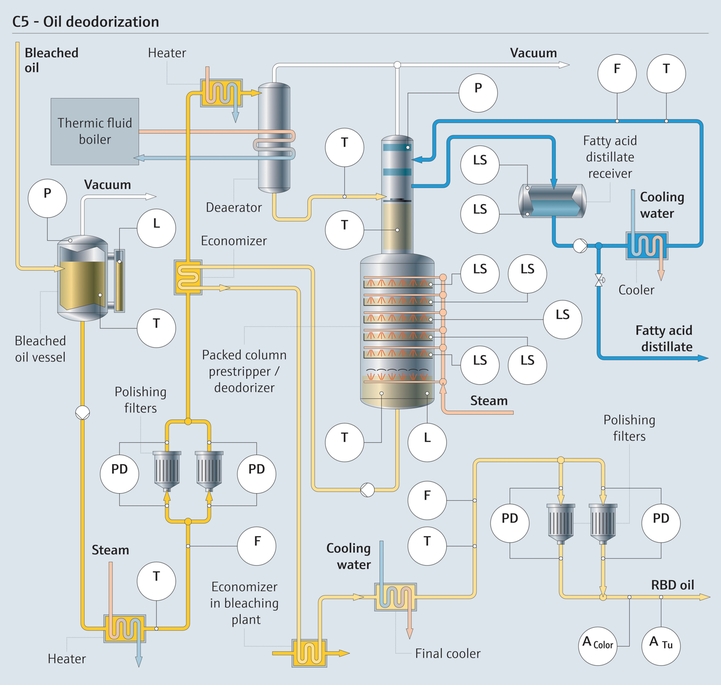

Desde a prensagem até o óleo comestível acabado, o óleo bruto passa por várias faixas de temperatura para garantir a qualidade do produto. Na etapa de desodorização, a temperatura do processo pode subir a 240 °C.

Nosso conhecimento em campo

A Endress+Hauser oferece uma ampla variedade de instrumentos de medição da temperatura para todas as especificações do processo, desde sensores de temperatura simples e compactos até transmissores modulares de alta tecnologia.

- Escolha o instrumento de temperatura mais adequado para as necessidades de seus processos usando um portfólio abrangente.

- Para a maioria das aplicações relacionadas à qualidade, recomendamos nosso sensor de temperatura intrinsecamente seguro iTHERM Moduline TM131

Monitoração segura da pressão e do vácuo nos recipientes

As células de medição de cerâmica são uma tecnologia comprovada para manter o nível de vácuo adequado nos recipientes durante o processo.

Nosso conhecimento em campo

Graças a uma célula de medição em cerâmica à prova de vácuo com membrana de detecção de quebra integrada, nosso transmissor de pressão Cerabar assegura um processo altamente seguro. A configuração rápida com faixa de medição ajustável facilita o comissionamento, reduz os custos e economiza tempo.

- Explore nosso transmissor digital de pressão CerabarPMC51.

Monitoramento preciso da vazão e volume em aplicações exigentes

Os medidores de vazão são usados para monitorar a transferência do óleo bruto dentro das etapas individuais do processo.

Nosso conhecimento em campo

Como resultado, a perda pode ser detectada e evitada para manter o rendimento em um alto nível constantemente. Além disso, os medidores de vazão Coriolis altamente precisos são usados para controlar a dosagem dos aprimoradores de processo, materiais de operação e aditivos, garantindo assim a qualidade do produto.

- Aproveite a medição simultânea de vazão mássica, a densidade, temperatura e viscosidade graças à medição de vazão Coriolis.

- Conheça o Proline Promass F 300, o medidor de vazão Coriolis com precisão premium, robustez e um transmissor ultracompacto.

- Evite interrupções do processo através de diagnósticos e verificações permanentes, graças à Heartbeat Technology. Ela assegura a operação segura da fábrica com custo otimizado durante todo o ciclo de vida.

A manutenção mantém seus processos seguros e eficientes

A manutenção regular é decisiva para garantir que todos os instrumentos necessários à produção operem com 100% de eficiência 24 horas por dia.

Nosso conhecimento em campo

Otimize seus esforços e atividades de manutenção em toda a sua base instalada com nossos serviços de manutenção de instrumentação

Benefícios

Como fabricante de óleos de cozinha, há uma pressão constante para economizar recursos e reduzir o tempo de inatividade, porém, mantendo em constante maximização a sua produtividade. É por isso que você precisa de um parceiro confiável. Nossa experiente equipe de especialistas na indústria pode ajudá-lo a escolher a tecnologia de medição certa para todos os parâmetros críticos de seu processo, possibilitando que você garanta a segurança e a qualidade do processo ao mesmo tempo.

Principais fatos

100%

Confiabilidade de medição devido à calibração garantida por nossos especialistas em manutenção global

Principais fatos

UM

Parceiro confiável com expertise em aplicação, indústria e processo na produção de óleos de cozinha

Principais fatos

24/7

Disponibilidade do sistema sem interrupção ou tempo parado

Como podemos ajudar

A Endress+Hauser oferece uma excelente experiência no setor e em aplicações. Oferecemos uma ampla gama de instrumentação de processo confiável e robusta para produzir óleos de cozinha de alta qualidade. Nossas soluções o apoiam em todas as etapas do seu processo de refino - desde degomagem, neutralização, branqueamento, desodorização até fracionamento a seco. Melhorias de processo sustentáveis ajudam você a evitar perdas e otimizar o desempenho do seu sistema de produção.

- Qualidade consistente do produto no mais alto nível

- Melhoria do processo para reduzir desperdícios e perdas

- Dados do processo em tempo real que servem de base para a manutenção inteligente