Especificações resumidas

Process temperature

0 to 140 °C (32 to 284 °F)

Process pressure

0 to max. 4 bar (0 to max. 58 psi) overpressure for manual actuation

Campo de aplicação

The Cleanfit CPA472D assembly is designed for harsh process conditions. It offers a great variety of rugged materials to operate your sensors safely even under high pressure, high temperature or in aggressive media. The assembly allows you to replace sensors without interrupting the process or to clean and calibrate them automatically via the optional control system. Benefit from easy, time-saving sensor handling and an extended operating life of the sensors.

The Cleanfit CPA472D is intended for installation in tanks or pipes in:

Chemical industry

Power plants

Biodiesel plants

It is suitable for use with pressures of up to 10 bar.

Benefícios

Extremely robust: Suitable for use with pressures of up to 10 bar and temperatures of up to 140° C even as PEEK, PVDF, conductive PVDF versions

Maximum chemical resistance ensures long operating times

No process interruption for electrode cleaning and calibration – saves maintenance time and costs

Flexible adaptation to all applications by great variety of materials and process connections

Histórias de sucesso

Mensurável e testável: Monitoramento com Teqwave

A limpeza eficiente de componentes é uma parte importante da produção de componentes fabricados industrialmente. A Borer Chemie AG, portanto, conta com a medição de concentração com o Teqwave F, I e T.

Leia o artigo completo

Análise de Líquidos em trens LNG

As várias etapas do processo em uma fábrica de liquefação de gás devem atender diferentes valores limites. Nossos produtos são ideais para esses processos.

Leia o artigo completo

Melhor operação de espessantes na Minera Valle Central

A medição de interface em espessantes é feita manualmente, enquanto a medição de turbidez é feita através da obtenção de amostras enviadas ao laboratório. Com a Endress+Hauser existe uma solução automatizada.

Leia o artigo completo

Produtos simples

Fácil de escolher, instalar e operar

Excelência técnica

Simplicidade

Produtos padrão

Confiável, robusto e baixa manutenção

Excelência técnica

Simplicidade

Excelência técnica

Simplicidade

Produtos especializados

Desenvolvidos para aplicações exigentes

Excelência técnica

Simplicidade

Versões FLEX

Excelência técnica

Simplicidade

Versão Fundamental

Atende suas necessidades básicas de medição

Excelência técnica

Simplicidade

Versão Lean

Lida com seus principais processos facilmente

Excelência técnica

Simplicidade

Seleção Extended

Otimiza seus processos com tecnologias inovadoras

Excelência técnica

Simplicidade

Versão Xpert

Controla suas aplicações mais difíceis

Excelência técnica

Simplicidade

Também pode ter interessar

Sobre nós

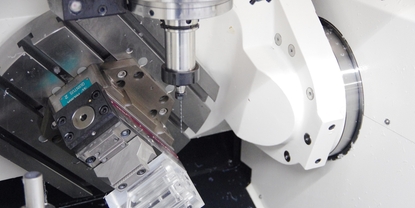

No assembly, no measurement!

The safety and operating comfort of an analytical measuring point starts with using the right assembly. Our flexible assembly production ensures that you get the right assembly for your needs.

Mais informações

Application

Chemical industry, biodiesel plants, power plants, plant design, tanks, process vats or pipes

Characteristic

For tanks and process vats and pipelines or pipes (min. DN80)

Material

Electrode holder, rinse chamber and raised face:

Dimension

Immersion depth: 146 or 280 mm (5.75 or 7.87 inch)

Process temperature

0 to 140 °C (32 to 284 °F)

Process pressure

0 to max. 4 bar (0 to max. 58 psi) overpressure for manual actuation

Connection

Process connections: Flange DN 50, DN 80, ANSI 2", JIS IS10K50A, internal thread G1¼

Application

Chemical industry, biodiesel plants, power plants, plant design, tanks, process vats or pipes

Characteristic

For tanks and process vats and pipelines or pipes (min. DN80)

Material

Electrode holder, rinse chamber and raised face:

Dimension

Immersion depth: 146 or 280 mm (5.75 or 7.87 inch)

Process temperature

0 to 140 °C (32 to 284 °F)

Process pressure

0 to max. 4 bar (0 to max. 58 psi) overpressure for manual actuation

Connection

Process connections: Flange DN 50, DN 80, ANSI 2", JIS IS10K50A, internal thread G1¼

11 documentos

Technical Information

Cleanfit P CPA472D

Retractable process assembly for pH, ORP and other industry electrodes

EN

PT

Alemão French Italiano Chinês

08/10/2013

01/06/2010

01/05/2006

Idioma:

Inglês

Versão:

08/10/2013

Tamanho do arquivo:

940.5 KB

Nome do arquivo:

TI00403CEN_1313.pdf

Technical Information Topcal S CPC310

Fully automatic measuring, cleaningand calibration system in hazardous

EN

PT

Alemão French Italiano Polonês Russo

22/07/2015

01/07/2006

Idioma:

Inglês

Versão:

22/07/2015

Tamanho do arquivo:

2 MB

Nome do arquivo:

TI00404CEN_1315.pdf

Operating Instructions

Cleanfit CPA472D

Retractable Process Assembly

EN

PT

Tcheco Alemão French Italiano Japonês Polonês

08/10/2013

01/09/2010

01/05/2006

Idioma:

Inglês

Versão:

08/10/2013

Tamanho do arquivo:

1.3 MB

Nome do arquivo:

BA00403CEN_1313.pdf

pH measurement in industrial processes

Selection and engineering guide for different industries and

Idioma:

Inglês

Versão:

02/12/2021

Tamanho do arquivo:

3.2 MB

Nome do arquivo:

CP00010CEN_1621_pH selection guide_2021.pdf

さまざまな産業およびアプリケーション向けのpH測定セレクションガイド

Idioma:

Japonês

Versão:

08/02/2024

Tamanho do arquivo:

5.8 MB

Nome do arquivo:

pH selection guide_CP00010C.pdf

pH-Messung in Industrieprozessen

Auswahl- und Engineering-Hilfe für verschiedene Industriebranchen und

Idioma:

Alemão

Versão:

01/12/2021

Tamanho do arquivo:

3.3 MB

Nome do arquivo:

CP00010CDE_1621_pH Auswahlhilfe_2021.pdf

L’automatisation des process vaut son pesant d’or

Memosens Les sondes de pH améliorent les process chez Agnico Eagle

Idioma:

French

Versão:

01/07/2016

Tamanho do arquivo:

673.1 KB

Nome do arquivo:

CS01496CFR-0216-Agnico Eagle.pdf

Process automation worth its weight in gold

Memosens pH sensors improve processes at Agnico Eagle

Idioma:

Inglês

Versão:

01/07/2016

Tamanho do arquivo:

1.5 MB

Nome do arquivo:

CS01496CEN_0116_Agnico Eagle goldmine.pdf

Prozessautomatisierung, die Gold wert ist

Memosens pH-Sensoren verbessernProzesse bei Agnico Eagle

Idioma:

Alemão

Versão:

01/07/2016

Tamanho do arquivo:

1.5 MB

Nome do arquivo:

CS01496CDE_0116_Agnico Eagle Goldmine.pdf

Product family: CleanFit P

Product root: CPA472D-

Idioma:

Inglês

Versão:

14/08/2020

Tamanho do arquivo:

187.9 KB

Nome do arquivo:

CPA472D_HE Ex_HE_01324_01.20.pdf

Product family: CleanFit P

Product root: CPA472D-

Idioma:

Inglês

Versão:

23/09/2020

Tamanho do arquivo:

209.7 KB

Nome do arquivo:

Klassifizierungsbescheinigung nach DGRL für CPA472D.pdf

Buscar peças de reposição pelo número no desenho

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

Kit CPA472D-KCl: Exit air seal bush PVDF

Código de pedido

71065953

Código de pedido

71217188

Código de pedido

71297785

CPA472D seals not medium cont.

Número do desenho

Código de pedido

6

71024454

CPA472D Sealing set inside flange Kalrez

Número do desenho

Código de pedido

10

71211749

CPA472D seal set flange inside Viton

Número do desenho

Código de pedido

10

71211751

CPA472D Seal set flange inside EPDM

Número do desenho

Código de pedido

10

71211752

CPA472D seal set G1 1/4" inside EPDM

Número do desenho

Código de pedido

10

71211736

CPA472D seal set G1 1/4" inside Viton

Número do desenho

Código de pedido

10

71211745

CPA472D seal set G1 1/4 inside Kalrez

Número do desenho

Código de pedido

10

71211748

CPA472D seals flange Viton mediumcont.

Número do desenho

Código de pedido

10

71024242

Sealings set CPA472D Viton

Número do desenho

Código de pedido

10

71027299

CPA472D Seals flange Kalrez mediumcont.

Número do desenho

Código de pedido

10

71024247

Sealings set CPA472D Kalrez

Número do desenho

Código de pedido

10

71027302

CPA472D Seals flange EPDM mediumcont.

Número do desenho

Código de pedido

10

71043257

Sealings set EPDM for CPA472D G1 1/4"

Número do desenho

Código de pedido

10

71043259

Kit CPA472/D: 20 pcs. O-ring ID14 W3 FPM

Número do desenho

Código de pedido

10

71090063

Kit CPA472/D: 2 pcs.O-ring ID14W3 KALREZ

Número do desenho

Código de pedido

10

71090065

Kit CPA472D Rinse chamber, IN, 316Ti,G,G

Número do desenho

Código de pedido

9

71214026

Spare parts CPA871, all materials

Código de pedido

XPC0003-

Kit CPA472D Rinse chamber, IN, Alloy,G,G

Número do desenho

Código de pedido

9

71214033

Kit CPA472D Rinse chamber, IN, 316Ti,G,N

Número do desenho

Código de pedido

9

71214227

Kit CPA472D Rinse chamber, IN, Alloy,G,N

Número do desenho

Código de pedido

9

71214228

Kit CPA472D Rinse chamber, IN, PEEK, F,G

Número do desenho

Código de pedido

20

71214230

Kit CPA472D Rinse chamber, IN, PVDF,F,G

Número do desenho

Código de pedido

20

71214232

Kit CPA472D Rinse chamber, IN,PVDF-C,F,G

Número do desenho

Código de pedido

20

71214233

Kit CPA472D Rinse chamber, IN, 316Ti,F,G

Número do desenho

Código de pedido

20

71214234

Kit CPA472D Rinse chamber, IN, Alloy,F,G

Número do desenho

Código de pedido

20

71214235

Kit CPA472D long, 361Ti, D18-I: Sensorg

Número do desenho

Código de pedido

7

71214236

Kit CPA472D long, Alloy, D18-I: Sensorg

Número do desenho

Código de pedido

7

71214237

Kit CPA472D short, 361Ti, D18-I: Sensorg

Número do desenho

Código de pedido

7

71214238

Kit CPA472D short, Alloy, D18-I: Sensorg

Número do desenho

Código de pedido

7

71214239

Kit CPA472D long, 316Ti, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214240

Kit CPA472D long, Alloy, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214242

Kit CPA472D short, 361Ti, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214243

Kit CPA472D short, Alloy, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214244

Kit CPA472D long, PEEK, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214245

Kit CPA472D short, PEEK, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214246

Kit CPA472D long, PVDF, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214247

Kit CPA472D short, PVDF, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214248

Kit CPA472D long, PVDF-C, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214249

Kit CPA472D short,PVDF-C, D25-I: Sensorg

Número do desenho

Código de pedido

7

71214250

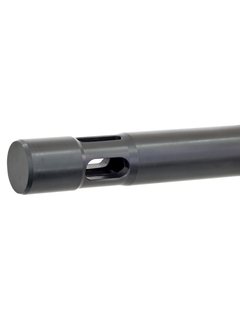

KIT CPA472D man.long Gel:retract.pipe

Número do desenho

Código de pedido

1

71026649

KIT CPA472D long pneum. Gel: retr. pipe

Número do desenho

Código de pedido

1

71026651

KIT CPA472D short hand Gel: retr. pipe

Número do desenho

Código de pedido

1

71026652

KIT CPA472D short pneum. Gel: retr. pipe

Número do desenho

Código de pedido

1

71026653

Kit CPA472D KCI-pipe manual

Número do desenho

Código de pedido

16

71102512

Kit CPA472D KCi-pipe pneumatic

Número do desenho

Código de pedido

16

71102513

KIT CPA472D long: Cylinder 1.4404 w.head

Número do desenho

Código de pedido

5

71026656

KIT CPA472D short: Cylinder1.4404 w.head

Número do desenho

Código de pedido

19

71026658

KIT CPA472D with flange: flange DN50

Número do desenho

Código de pedido

23

71026774

KIT CPA472D with flange: flange ANSI 2"

Número do desenho

Código de pedido

23

71026776

KIT 472D DN50+ANSI 2", PEEK: raised face

Número do desenho

Código de pedido

22

71026766

KIT 472D DN50+ANSI 2", PVDF: raised face

Número do desenho

Código de pedido

22

71026767

KIT 472D DN50+ANSI 2"PVDF-c: raised face

Número do desenho

Código de pedido

22

71026768

KIT 472D DN50+ANSI 2", HC4: raised face

Número do desenho

Código de pedido

22

71026770

KIT 472D DN50+ANSI 2",1.4571:raised face

Número do desenho

Código de pedido

22

71026772

KIT CPA472D with flange: flange DN80

Número do desenho

Código de pedido

23

71026775

KIT CPA472D DN80 PEEK: raised face

Número do desenho

Código de pedido

22

71026781

KIT CPA472D DN80 PVDF: raised face

Número do desenho

Código de pedido

22

71026783

KIT CPA472D DN80 PVDF-cond: raised face

Número do desenho

Código de pedido

22

71026784

KIT 472D DN80 HC4: raised face

Número do desenho

Código de pedido

22

71026785

KIT CPA472D DN80 1.4571: raised face

Número do desenho

Código de pedido

22

71026787

KIT CPA472D with flange: JIS flange

Número do desenho

Código de pedido

23

71085857

KIT 472D JIS flange, PEEk: raised face

Número do desenho

Código de pedido

22

71085850

KIT 472D JIS flange, PVDF: raised face

Número do desenho

Código de pedido

22

71085851

KIT 472D JIS flange, PVDF-C: raised face

Número do desenho

Código de pedido

22

71085852

KIT 472D JIS flange, HC4: raised face

Número do desenho

Código de pedido

22

71085854

KIT 472D JIS flange, 316TI: raised face

Número do desenho

Código de pedido

22

71085856

Kit CPA472D/473: 20retaining washer

Número do desenho

Código de pedido

18

71103282

KIT 472D HC4, G1/4": Swagelok rinse conn

Número do desenho

Código de pedido

21

71026794

KIT 472D 1.4571 G1/4: Swagelok rinse con

Número do desenho

Código de pedido

21

71026796

KIT CPA47x airflow throttle+dummyplug SS

Número do desenho

Código de pedido

2.8

51503732

KIT CPA47X: Throttel check valve

Número do desenho

Código de pedido

2

71329949

KIT CPA: elbow conn. R1/8 OD6 SS 2 pcs.

Número do desenho

Código de pedido

3

71027935

KIT CPA47x: sealing plug M12x1 (10 pcs.)

Número do desenho

Código de pedido

11

51503733

KIT CPA47x:stop bolt with handle (1 pc.)

Número do desenho

Código de pedido

4

51503731

KIT CPA472D: cyl. screw M6x70 20 pcs.

Número do desenho

Código de pedido

15

71026789

KIT CPA471/472 cyl. screw M6x45 20 pcs.

Número do desenho

Código de pedido

17

51503738

Splash protection cap for assemblies

Número do desenho

Código de pedido

25

51517522

Protective pipe short f.process assembly

Número do desenho

Código de pedido

26

51518182

hose support f. Ø6 und Ø8 KCL hose

Código de pedido

51518208

Protective sleeve wide f. KCl-electr.

Número do desenho

Código de pedido

27

50080430

Pneum. proxim. switches f.retrofitting

Número do desenho

Código de pedido

12

51502874

KIT CPA47x electr. proxim.switches

Número do desenho

Código de pedido

13

51502873

Built-in adapt.straight,Size25,1.4404

Código de pedido

51500328

Built-in adapt.oblique,Size 25,1.4404

Código de pedido

51500327

flange- welding socket DN50,PN16

Código de pedido

71098682

Dummy plug 316L, G 1 1/4 inch internal

Código de pedido

51502800

Locking screw G1/4 inch GL8mm

Código de pedido

50092264

Hose connection set PVDF, G 1/4"-DN 12

Código de pedido

50090491

KIT CPA47x pneu.connection G1/8 AD6 10p

Código de pedido

51503730

Sua privacidade é muito importante

Usamos cookies para melhorar sua experiência de navegação, coletamos estatísticas para otimizar a funcionalidade do site e entregar anúncios e conteúdo personalizados.

Ao selecionar "Aceitar todos", você consente nosso uso de cookies.Política de cookies .

Personalizar

Aceitar apenas o essencial

Aceitar todos