Especificações resumidas

-

Max. measurement error

Mass flow (liquid): ±0.5 % (standard), ±0.15 % (option)

Mass flow (gas): ±0.75 % -

Measuring range

0 to 180 000 kg/h (0 to 6615 lb/min)

-

Medium temperature range

–40 to +150 °C (–40 to +302 °F)

-

Max. process pressure

PN 40, Class 300, 40K

-

Wetted materials

Measuring tube: 1.4539 (904L)

Connection: 1.4404 (316/316L)

Campo de aplicação

Promass K is the cost-efficient Coriolis solution for elementary mass flow measuring tasks. It provides dependable measurement in basic applications featuring air, gas, fuel and water. With its straightforward hard- and software design, Promass K 10 simplifies every step in its life cycle from engineering to servicing at usual Endress+Hauser quality. Heartbeat Technology enables measurement reliability and extension of recalibration cycles.

Measuring principle operates independently of physical fluid properties such as viscosity or density

Measurement of liquids and gases in utility processes and basic applications

Device properties

Compact dual-tube sensor

Medium temperature up to +150 °C (+302 °F)

Process pressure up to 100 bar (1450 psi)

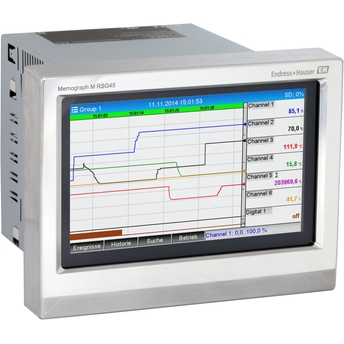

System integration with HART, Modbus RS485

Flexible operation with app and optional display

Benefícios

Cost-effective general-purpose device – alternative to mechanical flowmeters

Fewer process measuring points – multivariable measurement (flow, density, temperature)

Space-saving installation – no in-/outlet run needs

Optimum usability – operation with mobile devices and SmartBlue app or display with touch screen

Simple, time-saving commissioning – guided parameterization in advance and in the field

Integrated verification – Heartbeat Technology

Vídeos

Versão Lean

-

Produtos padrão

- Confiável, robusto e baixa manutenção

Excelência técnica

Simplicidade

-

Produtos com tecnologia de ponta

- Altamente funcional e prático

Excelência técnica

Simplicidade

-

Produtos especializados

- Desenvolvidos para aplicações exigentes

Excelência técnica

Simplicidade

Variável

| Versões FLEX | Excelência técnica | Simplicidade |

|---|---|---|

Versão Fundamental Atende suas necessidades básicas de medição |

Excelência técnica

|

Simplicidade

|

Versão Lean Lida com seus principais processos facilmente |

Excelência técnica

|

Simplicidade

|

Seleção Extended Otimiza seus processos com tecnologias inovadoras |

Excelência técnica

|

Simplicidade

|

Versão Xpert Controla suas aplicações mais difíceis |

Excelência técnica

|

Simplicidade

Variável |

Loading alternative products

Loading alternative products

Predecessor

-

-

Informações Técnicas (TI)

Proline Promass K 10

Versão em português - 10/2022

Medidor de vazão Coriolis

EN PT 03/10/202201/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

3.6 MB

Nome do arquivo:

TI01581DPT_0222-00.pdf

-

-

-

Instruções de Operação (BA)

Proline Promass K 10

Versão em português - 10/2022

Medidor de vazão Coriolis HART

EN PT 03/10/202201/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

3.9 MB

Nome do arquivo:

BA02074DPT_0222-00.pdf

-

-

-

Informações Técnicas (TI)

Proline Promass K 10

Medidor de vazão Coriolis

EN PT 03/10/202201/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

3.6 MB

Nome do arquivo:

TI01581DPT_0222-00.pdf

-

-

-

Instruções de Operação (BA)

Proline Promass K 10

Medidor de vazão Coriolis

HARTEN PT 03/10/202201/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

3.9 MB

Nome do arquivo:

BA02074DPT_0222-00.pdf

-

-

-

Instruções de Operação (BA)

Proline Promass K 10

Medidor de vazão Coriolis

Modbus RS485EN PT 03/10/202212/07/202101/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

3.3 MB

Nome do arquivo:

BA02075DPT_0322-00.pdf

-

-

-

Parâmetro do Equipamento (GP)

Proline Promass 10

Coriolis flowmeter

Modbus RS485EN PT 03/10/202201/07/2021Idioma:

Inglês

Versão:

03/10/2022

Tamanho do arquivo:

1.7 MB

Nome do arquivo:

GP01160DEN_0222-00.pdf

-

-

-

Parâmetro do Equipamento (GP)

Proline Promass 10

Coriolis flowmeter

HARTEN PT 03/10/202201/07/2021Idioma:

Inglês

Versão:

03/10/2022

Tamanho do arquivo:

1.6 MB

Nome do arquivo:

GP01159DEN_0222-00.pdf

-

-

-

Instruções curtas (KA)

Proline Promass K

Sensor Coriolis

EN PT 01/07/2021Idioma:

Português

Versão:

01/07/2021

Tamanho do arquivo:

753 KB

Nome do arquivo:

KA01491DPT_0121.pdf

-

-

-

Instruções curtas (KA)

Medidor de vazão Proline 10

Transmissor HART

com sensor CoriolisEN PT 03/10/202201/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

1.2 MB

Nome do arquivo:

KA01498DPT_0222-00.pdf

-

-

-

Instruções curtas (KA)

Medidor de vazão Proline 10

Transmissor Modbus RS485

Transmissor com sensor CoriolisEN PT 03/10/202201/07/2021Idioma:

Português

Versão:

03/10/2022

Tamanho do arquivo:

1.2 MB

Nome do arquivo:

KA01500DPT_0222-00.pdf

-

-

-

Instruções de Instalação (EA)

EA Alteration of the display module

Proline 10

EN PT 15/03/202403/10/202201/04/2022Idioma:

Inglês

Versão:

15/03/2024

Tamanho do arquivo:

874.5 KB

Nome do arquivo:

EA01362DA2_0324-00.pdf

-

-

-

Instruções de Instalação (EA)

Replacing the transmitter, non Ex/Zone 2/Div. 2/Ex db/Zone 1/Div. 1

Proline 10

EN PT 15/03/202303/10/202204/04/202220/08/2021Idioma:

Inglês

Versão:

15/03/2023

Tamanho do arquivo:

1.4 MB

Nome do arquivo:

EA01350DA2_0423-00.pdf

-

.jpg)